Types of gloves

1.Synthetic gloves.

- For its design:

• With support, using materials such as cotton, nylon, taeki fiber... before Coating them with synthetic material (usually latex, nitrile and polyurethane).

• Without support, directly introducing the glove mold in synthetic material (Nitrile, latex, neoprene...).

- For the materials used:

• Latex gloves, nitrile, PVC...

2.Leather gloves.

- For its design: American type gloves, driver type, welder type...

- For the materials used:

• Flower skin: using the outside of the skin (greater comfort and skill).

• Skin suede: using the internal part of the skin (greater abrasion resistance).

DEFINITIONS

- Glove: Epi destined to protect the hand or part of it against risks.

- Risk: unwanted situation that can cause damage to the health of the worker.

- Glove palm: the glove part that covers the palm of the hand.

- Bush of the glove: the part of the glove that covers the back of the hand.

- Dexterity: the manipulation capacity to do a job is measured.This related to the thickness, elasticity and deformability of the glove.

- Provision level: it is the number that indicates the value obtained in the trial corresponding according to the specific standard.

THE MATERIALS

- Synthetic materials such as nylon (abrasion and tearing), Taeki fiber (cutting and thermal protection), PVC (abrasion and chemicals such as greases, oils and alcohols), Neoprene (temperature and chemicals).

- Leather (Flower and Split Leather), comfortable and breathable material that offers good mechanical properties (especially abrasion and tearing).

- Coatings:

• Latex. Comfort, elasticity and dexterity. Resistance to aqueous chemicals. Excellent grip and good abrasion resistance.

• Polyurethane. Elasticity, resistance to abrasion and tension. Resistant to alcohols, hydrocarbons, and solvents. Very good grip, good abrasion resistance and breathability.

• Nitrile. Synthetic rubber resistant to oils, lubricants and petroleum products. Good mechanical and perforation resistance. Very chemically resistant.

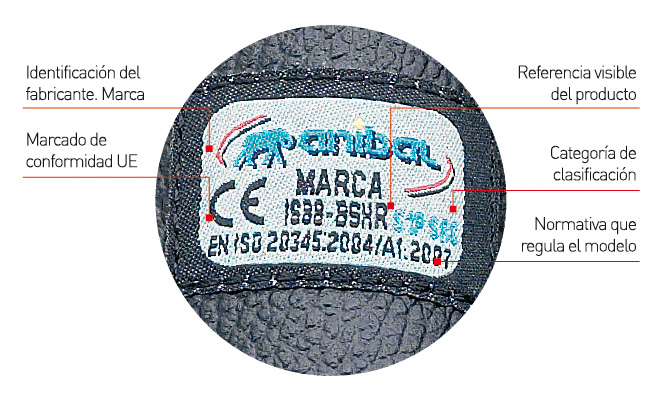

GLOVE MARKING

GLOVE CHOICE

Other factors to take into account are the environment (indoor/outdoor, humidity...etc).

2º Identify the user's size: Check your size.

The choice of size is very important not only for the comfort, ergonomics and protection of the user, but also for the precise performance of the work. A poor choice of size can lead us to perform work less accurately (inefficiency), to greater risk (errors...) and to a longer exposure to risk as it takes longer to complete the task.

- Category 1: Gloves that, due to their simple design, allow the user to judge for themselves their effectiveness against minimal risks and whose effects, when adjustable, can be perceived in time and without danger to the user: superficial mechanical attacks, maintenance products whose effects are easily reversible, shocks and vibrations that do not affect vital parts...

• These gloves must exceed EN420, a harmonized standard that regulates the minimum requirements to be met by work gloves: dexterity, PH, chromium content, size, safety,…

• The marking that gloves under category 1 must have is:

- Identification of the manufacturer or representative (logo, NIF…)

- Reference or model.

- Size.

- CE marking. - Category 2: Gloves intended to avoid risks of all types that could not cause very serious injuries or death (intermediate risks).

• These gloves must exceed, in addition to EN420, the harmonized standard that regulates the risk against which this glove is recommended.

• The marking that gloves under category 2 must have is:

- Identification of the manufacturer or representative.

- Pictogram of the risk against which it is recommended.

- Resistance levels.

- Model or reference.

- Size.

- Pictogram related to the informative brochure.

- CE marking.

• Compliance with the standard must be made by a laboratory notified by the CE, issuing a CE type certificate. - Category 3: Gloves intended to protect the user from a mortal danger or danger that could seriously and irreversibly damage health, without its immediate effect being discovered in time.

These gloves must exceed, in addition to EN420, the harmonized standard that regulates the risk against which this glove is recommended.

The marking that gloves under category 3 must have is:

- Identification of the manufacturer or representative.

- Pictogram of the risk against which it is recommended.

- Resistance levels.

- Model or reference.

- Size.

- Pictogram related to the informative brochure.

- CE marking plus the identification number of the Notified Control Body responsible for CE quality control in the production phase.

• They must be certified by a notified body and the manufacturer adopt one of the CE quality assurance systems regulated for their marketing according to RD 1407/1992.

| PICTOGRAM | RULE | DESCRIPTION | |||||||||||||||||||||

| EN 388:2016 | Mechanical risk. Abrasion, Cutting, Tearing and Puncture. Maximum level of benefit: 4 (except for cutting, which is level 5).

|

||||||||||||||||||||||

| EN 374-1 | Chemical risk. |

||||||||||||||||||||||

| EN 374-5 | Risk due to microorganisms (bacteria and fungi). If the virus test is passed, "virus" will be written below the logo. | ||||||||||||||||||||||

| EN 407 | Thermal risk (temperature between 50ºC and 100ºC). Flammability, Contact heat, Convective heat, Radiant heat, Small splashes of molten metals, Large masses of molten metals. | ||||||||||||||||||||||

| EN 511 | Risks due to cold (up to -50ºC). Convective cold, contact cold, Impermeability to water. | ||||||||||||||||||||||

| EN 12477 | Welding risks. They are classified into two types. Type A and Type B. They must be tested for standards EN388 (mechanical risks) and EN407 (thermal risks) and pass minimum levels for each of the standards. These levels and dexterity will give us the type of glove. In general, it is recommended to use Type B gloves in jobs where a high level of dexterity is necessary (for example: TIG welding). | ||||||||||||||||||||||

| EN 1082-1 | Risks from cuts and punctures caused by hand knives. | ||||||||||||||||||||||

| EN 60903 | Electric risk. They are classified into 6 classes according to their maximum usage voltage.

|

- Category 1: Those work clothing that, due to its simple design, the user can judge for himself its effectiveness against minimal risks, and whose effects, when gradual, can be perceived in time and without danger to the user, such as mechanical attacks from superficial effects or atmospheric agents that are not exceptional or extreme.

• This clothing must exceed EN 13688, a harmonized standard that regulates the minimum requirements to be met by Work Clothing, dimensional change after washing, size designation, labeling, physiological properties, color fastness,... These garments must exceed, in addition to EN13688, the harmonized standard that regulates the risk against which it is recommended, for example: EN14058 : Protective clothing against cold environments (between -5ºC and 10ºC).

EN14058 : Protective clothing against cold environments (between -5ºC and 10ºC).  EN343 : Rain protection clothing.

EN343 : Rain protection clothing.

• The marking that these garments in category 1 must bear is:

- identification of the manufacturer or representative.

- model or reference.

- size.

- CE marking.

- maintenance instructions.

- composition. - Category 2: Clothing intended to protect against intermediate or all types of risks that could not cause very serious injuries or death.

• These garments must exceed, in addition to EN13688, the harmonized standard that regulates the risk against which it is recommended, for example: EN342 : Protective clothing against the cold to protect against ambient temperatures between -5ºC and -50ºC.

EN342 : Protective clothing against the cold to protect against ambient temperatures between -5ºC and -50ºC.  EN11611 : Protective clothing used during welding and related processes.

EN11611 : Protective clothing used during welding and related processes.  EN11612 : Protective clothing for workers exposed to heat (temperature below 100ºC).

EN11612 : Protective clothing for workers exposed to heat (temperature below 100ºC).  EN20471 : High Visibility Protective Clothing.

EN20471 : High Visibility Protective Clothing.  EN1149-5 : Antistatic protective clothing. EN14116 Protective clothing against heat and flame (limited flame spread)

• The marking that these garments must carry is the same as that of category 1, adding the pictogram indicating the risk and its resistance levels.

EN1149-5 : Antistatic protective clothing. EN14116 Protective clothing against heat and flame (limited flame spread)

• The marking that these garments must carry is the same as that of category 1, adding the pictogram indicating the risk and its resistance levels.

- Category 3: Clothing intended to protect the user from a mortal danger or that may seriously and irreversibly damage health without its immediate effect being discovered in time. This clothing must exceed, in addition to EN13688, the harmonized standard that regulates the risk against which this clothing is recommended:

EN13034 Limited protective clothing against liquid chemicals (Type 6).

EN13982-1 Chemical protective clothing against suspended solid particles (Type 5)

EN14605 Protective clothing with spray-tight joints (Type 4)

EN14605 Protective clothing against liquid chemicals (Type 3)

EN1073-2 Non-ventilated protective clothing against contamination radioactive particles

EN14126 Protective clothing against biological agents

EN61482 Protective clothing against electric arc

The marking that these garments must bear is the same as that of category 2, but adding to the CE marking the identification number of the notified control body in charge of CE quality control in the production phase.They must be certified by a notified body and the manufacturer must adopt one of the CE quality assurance systems regulated for their marketing according to RD 1407/1992.

Measurements and sizes table

| JUMPSUITS - JACKETS - JACKETS - ROBES | ||||||||||||

| SIZE | 48(S) | 50(M) | 52(M) | 54(L) | 56(L) | 58(XL) | 60(XL) | 62(XXL) | 64(XXL) | 66 | 68 | 70 |

| Chest (cm) | 92-96 | 96-100 | 100-104 | 104-108 | 108-112 | 112-116 | 116-120 | 120-124 | 124-128 | 128-132 | 132-136 | 136-140 |

| Height (cm) | 152-158 | 158-164 | 164-170 | 170-176 | 176-182 | 182-188 | 188-194 | 194-200 | 194-200 | 194-200 | 194-200 | 194-200 |

| PANTS | |||||||||||

| SIZE | 38(S) | 40(M) | 42(M) | 44(L) | 46(L) | 48(XL) | 50(XL) | 52(XXL) | 54(XXL) | 56(XXXL) | 58(XXXL) |

| Waist(cm) | 72-76 | 76-80 | 80-84 | 84-88 | 88-92 | 92-96 | 96-100 | 100-104 | 104-108 | 108-112 | 112-116 |

| Height (cm) | 152-158 | 158-164 | 164-170 | 170-176 | 176-182 | 182-188 | 188-194 | 194-200 | 194-200 | 194-200 | 194-200 |

| SHIRTS | ||||||||

| SIZE | 37/38(S) | 39/40(M) | 41/42(L) | 43/44(XL) | 45/46(XL) | 47/48(XXL) | 49/50 | 51/52 |

| Chest (cm) | 96-100 | 100-104 | 104-108 | 108-112 | 112-116 | 116-120 | 120-124 | 124-128 |

| Height (cm) | 158-164 | 164-170 | 170-176 | 176-182 | 182-188 | 188-194 | 194-200 | 194-200 |

| WATER SUITS - VESTS - JACKETS - PARKAS - POLO SHIRT - T-SHIRTS - JERSEYS - SWEATERS | |||||

| SIZE | Yes | M | l | XL | XXL |

| Chest (cm) | 84-92 | 92-100 | 100-108 | 108-116 | 116-124 |

| Height (cm) | 164-170 | 170-176 | 176-182 | 182-188 | 188-194 |

Measurements and sizes table

| PANTS | |||||

| SIZE | Yes | M | l | XL | XXL |

| Waist(cm) | 72-76 | 76-84 | 84-92 | 92-100 | 100-108 |

| Height (cm) | 152-158 | 158-170 | 170-182 | 182-194 | 194-200 |

- Category 2: Flame retardant (heat and flame)

EN 11612

EN 11612

A: Limited flame spread (A1-A2).

B: Convective heat (B1-B2-B3).

C: Radiant heat (C1-C2-C3-C4).

D: Molten aluminum splashes (D1-D2-D3)

E: Cast iron splashes (E1-E2-E3)

F. Contact heat (F1-F2-F3). - Category 2: Welding

EN 11611

EN 11611

- CLASS 1: Small welding sparks (finer fabrics)

- CLASS 2: Large welding sparks (thicker, higher-tech fabrics or split leathers) - Category 3: Clothing designed to withstand temperatures >100ºC. or certified for Electric Arc…(IEC 61482).

OTHER COMPLEMENTARY STANDARDS:

IEC61482 electric arc. It is not an electrical insulation standard...it is about avoiding a burn caused by this phenomenon. It is classified into class 1 and class 2, according to its degree of protection.

EN1149-5 static electricity. Prevents accumulation of static electricity on the body to reduce the possibility of generating a spark and therefore an explosion...only EN1149, followed by "-5" is what guarantees that the garment is antistatic as a whole.

EN20471 for situations in which it is necessary to signal the presence of a user in conditions of low visibility. They can be class 1, class 2 or class 3.

The directive that regulates equipment used in environments with explosive atmospheres requires the use of fireproof (EN11612) and antistatic (EN1149-5) clothing.

- Category 3:

TYPE 1 : Gas-tight garments.

TYPE 1 : Gas-tight garments.  TYPE 2 : Non-gas tight garments.

TYPE 2 : Non-gas tight garments.  TYPE 3 : Liquid-impermeable garments.

TYPE 3 : Liquid-impermeable garments.  TYPE 4 : Spray-tight garments.

TYPE 4 : Spray-tight garments.  TYPE 5 : Particle-tight garments.

TYPE 5 : Particle-tight garments.  TYPE 6 : Garments partially impervious to splashes.

TYPE 6 : Garments partially impervious to splashes.

Other Risks EN 1149-5 : antistatic.

EN 1149-5 : antistatic.  EN ISO 14116 : flame retardant.

EN ISO 14116 : flame retardant.  EN 14126 : biological.

EN 14126 : biological.  EN 1073-2 : radioactive particles.

EN 1073-2 : radioactive particles.

EN20471 : High Visibility clothing requirements.

EN20471 : High Visibility clothing requirements.

X= Garment class (3, 2 or 1).

This clothing is intended to visually signal the presence of the user in order to be detected in risky conditions, under daylight and under the light of a car's headlights in the dark.

The benefits are given by color and retroreflection. Also due to the minimum areas and the arrangement of the materials used in its preparation.

- Background material : Colored fluorescent material intended to be highly visible. Standardized colors for background material are:

Fluorescent Yellow

Fluorescent Red-

Orange Fluorescent Red

- Retroreflective Material : Material that is retroreflective and is exempt from meeting the background material requirements.

3 Classes of protective clothing are defined according to the minimum areas of the materials that the garment incorporates:

Class 3 (the one with the greatest visibility in urban and rural environments).

Class 2

Class 1 (the one with the least visibility).

The new standard only allows retroreflective bands with a Level 2, so the lower digit of the pictogram disappears as it is an essential requirement for the certification of garments (there is no Level 1).

-

EN20345 for safety footwear for professional use: CLASSIFICATION I (Footwear made of leather and other materials)

• SB : Footwear with safety stop (inside toe cap) resistant to 200 J.

• S1 : SB + Closed heel area + Antistatic + Absorption of energy in the heel area.

• S2 : S1 + Resistance to water penetration and absorption.

• S1P : S1 + Sole penetration resistance (P).

• S3 : S2 + Sole penetration resistance (P) + Sole with ridges.CLASSIFICATION II (All-rubber or all-polymeric footwear, such as wellies)

• SB : Footwear with safety stop (inside toe cap) resistant to 200 J.

• S4 : SB + Antistatic footwear + Energy absorption in the area of the heel. heel.

• S5 : S4 + Sole penetration resistance (P) + Sole with ridges. - EN20347 for work footwear for professional use: CLASSIFICATION I (Footwear made of leather and other materials)

CLASSIFICATION I

(Footwear made of leather and other materials)01

• 0B : Fundamental properties.

• 01 : 0B + Closed heel area + Antistatic + Energy absorption in the heel area.

• 02 : 01 + Resistance to water penetration.

• 03 : 02 + Sole penetration resistance (P) + Sole with ridges.CLASSIFICATION II

(All-rubber or

all-polymeric footwear,

eg wellies)02

• 0B : Fundamental properties.

• 04 : OB + Antistatic footwear + Energy absorption in the heel area.

• 05 : 04 + Penetration resistance + Sole with ridges.

SYMBOLOGY

|

|

|

|

|

| Resistant to 200 J | Anti-perforation insole | Antistatic | Water resistant | Oil resistant |

|

|

|

|

|

|

| Hydrocarbon resistant | Shock absorption | Non-slip sole | Reinforced toe | Heat resistance | Cold resistance |

Footwear marking

Metal Free

-

Our METAL FREE footwear is designed under the requirements of EN20345 for safety footwear, using no metal component in its structure , seeking a high level of comfort that does not conflict with its protection capacity.

The safety stop is made of composite (composite resin), making it lighter and non-magnetic , recovering its shape after an impact, thus facilitating the release of the foot. The anti-perforation insole , made with the same type of material or with latest generation puncture-resistant fabrics, in addition to lightness and thermal insulation , achieves great flexibility and great torsion, also covering a greater plantar surface of the foot.

General Regulations

This type of PPE is classified within category III , which includes complex design equipment intended to protect against any mortal danger or that may seriously and irreversibly harm health, which is why the manufacturer must prepare a CE declaration of conformity. after a notified body has issued an EC type certificate and carried out a manufacturing check.

General Requirements.

Requirements applicable to all PPE:

Ergonomics, Safety, Comfort and Efficiency.

Complementary Requirements.

When PPE has adjustment systems, it must be manufactured in such a way that, once adjusted, it cannot (under normal conditions of use) become unfit regardless of the user's will.

_Norm EN353-2 Anti-fall sliding devices with flexible anchor line.

_Norm EN354 Lashing elements.

_Norm EN355 Energy absorbers.

_EN358 Epis standard for restraint in the work position and prevention of falls from height. Fastening and retention belts and restraint lashing components. Applicable to equipment intended to keep the user in their working position (Restraint) and prevent them from reaching a place where a fall from a height could occur (Retention). In no case should a restraint or restraint system be used as a fall arrester.

_EN360 Standard Retractable fall arrest devices.

_Norm EN361 Anti-fall harnesses.

_EN362 Standard Connectors.

_EN363 Standard This standard specifies the terminology and general requirements of fall arrest systems used as PPE against falls from a height. They must be designed and manufactured with a high level of protection that does not generate risks, easy to put on, light and without misalignments, and that allow a correct position after stopping.

_EN364 Standard Regulates testing methods.

_EN365 Standard General requirements for instructions for use and marking.

_EN795 Standard Anchoring devices.

_Norm EN813 Suspended Work. Marking CE

marking

(as they are category 3 personal protective equipment) followed by the number of the authorized control body.

Manufacturer name.

Device model.

Serial or lot number.

Month and year of manufacture.

Manufacturing materials.

Instructions for Use

Name of the manufacturer or distributor and their address. Model.

Storage, cleaning and maintenance instructions. Other indications that the manufacturer considers appropriate.

Maintenance According to the EN365

standard , each equipment must be checked by the user visually before each use to find possible damage. The useful life of STEELPRO equipment is approximately 5 years, always depending on the conditions of use and maintenance (daily use, exposure to the sun, rubbing with edges and other devices, transportation... etc. shorten the life of the equipment).

They must undergo an annual review by the manufacturer from the date of first use, and be replaced 5 years from the date of manufacture or date of first use. For annual reviews, the cost, transportation, etc. must always be assessed. compared to the cost of acquiring a new product (with greater guarantees as it is new and unused equipment) and with a more recent manufacturing date.

Due to the current cost of the equipment, it is usually more advisable from the point of view of cost and, above all, safety, to replace the equipment with new ones.

SYMBOLOGY

|

|

|

|

| sternal latch | dorsal hitch | positioning hitch | seat hitch |

General Regulations

EN352-1 Earmuffs

EN352-2 Earplugs

EN352-3 Earmuffs attached to a protective helmet

EN352-4 Level-dependent earmuffs

All hearing protectors belong to Category 2 (3 if harmful noise) of the PPE classification .

Evaluation of Noise Exposure

The daily exposure of a worker to noise, equivalent daily level, is expressed in dB(A), a measure calculated and referred to 8 hours a day. In jobs where the equivalent daily level exceeds 80 dB(A), the employer must provide hearing protectors to exposed workers. In jobs where the equivalent daily level or the Peak level exceeds 85 dB(A) respectively, all workers must use hearing protectors, the mandatory use of which will be posted according to the provisions of RD1316/89.

Evaluation of acoustic attenuation

The evaluation methods are included in the ISO 4869 standard:

The Octave Band method specifies eight attenuation values in decibels at eight different frequencies: 63 125 250 1000 2000 4000 6000 8000. The assumed protection values (APVf ) are minimum attenuation values of each referred frequency. These values are obtained by subtracting, for each reference considered, the average attenuation of the protector at High (H) and Low (L) frequencies.

The HML method specifies three attenuation values in decibels, determined from the octave band attenuation of the protector. The letters HML represent the average attenuation of the protector at High (H), Medium (M) and Low (L) frequencies.

The SNR method specifies a single attenuation value, Simplified Noise Level Reduction. The SNR value indicates the average attenuation of the protector across all frequency bands.

The HML and SNR values are not derived from an arithmetic mean of the assumed protection values of the octave band measurement, but are derived from the application of logarithmic forms indicated in the ISO 4869 standard.

Selection and use

Avoid overprotection: You should avoid choosing protectors that provide too high noise attenuation as this may cause communication problems or be less comfortable, which will reduce the time the user wears them.

Comfort: the most effective protector is the one that is used continuously. That is why they should be as comfortable as possible. In this way the user is motivated to wear it throughout the entire exposure to noise, a determining factor for real protection. It is advisable that the protector be chosen by the user.

Type of protector: in environments with high temperatures and large accumulation of dust, it is preferable to use earplugs, while in situations of repeated exposure to short-term noise, it is preferable to use earmuffs or earplugs with a harness since their placement and removal is faster.

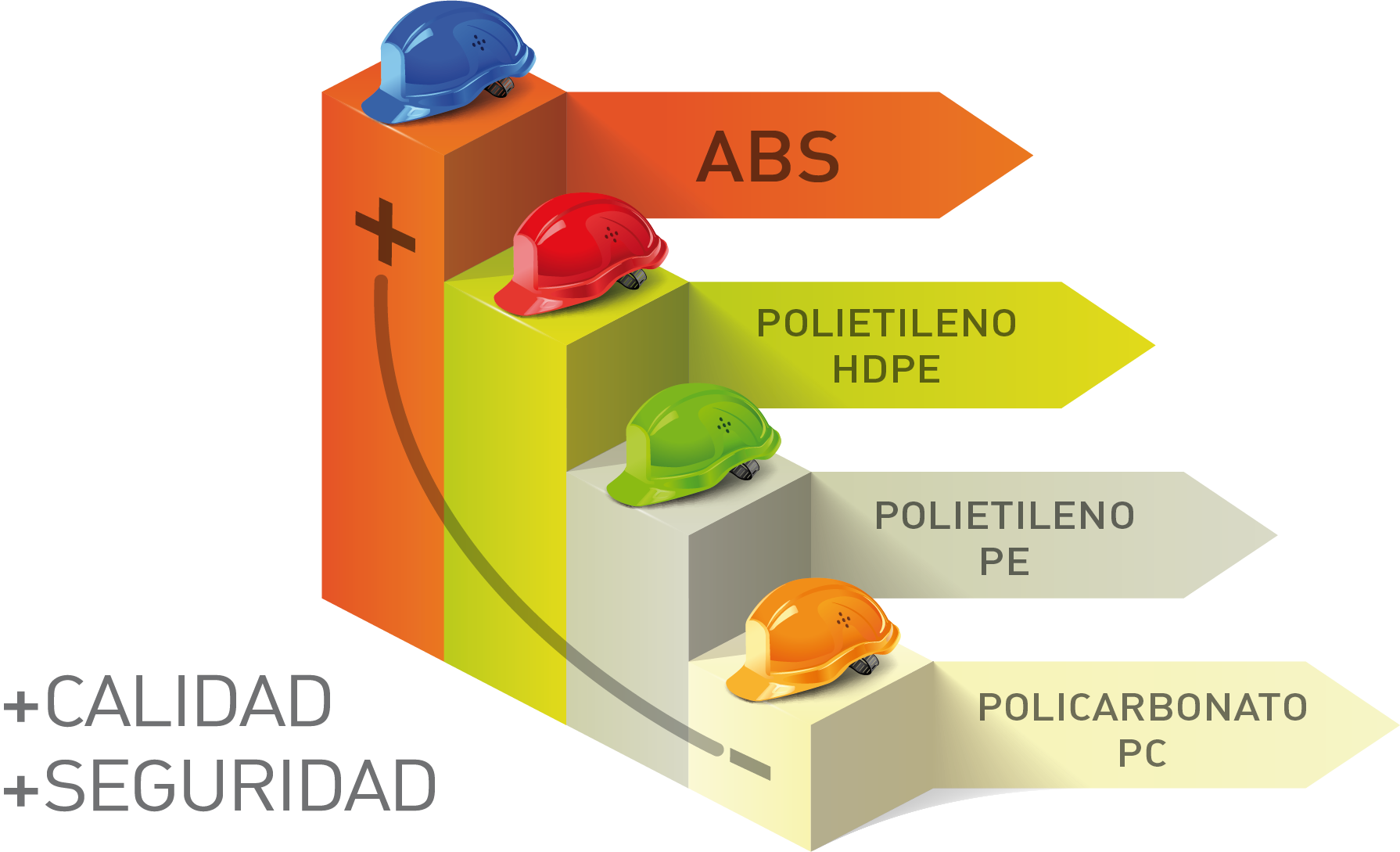

General Regulations

European Reference Standards

Category II

EN 397 Safety Helmets for Industry.

The helmet must include at least one cap and one harness. Protection against the effect of falling or thrown objects, or moving or suspended loads.

Additional requirements:

• - 30ºC

• 440V

• Molten metal

EN 812 Industrial anti-shock caps.

Industrial anti-shock caps serve to protect the wearer's head if the head hits hard and immobile objects. DO NOT confuse an anti-impact cap with a safety helmet, the risks to be covered are different.

Category III

EN 50365 Helmets certified for electrical risk (1000V).

All equipment belongs to category II (medium or high risk) of the PPE classification.

European Standard EN 397 specifies the physical performance requirements, test methods and marking requirements for safety helmets for industry. The mandatory requirements apply to helmets for general use in industry. Additional optional compliance requirements are included to apply only when specifically required by the helmet manufacturer.

Physical Demands

For those parts of the helmet that come into contact with the skin, materials known to cause skin irritation or any adverse health effects should not be used.

Those parts of the helmet, its accessories or fixing elements that are in contact with the user or likely to be, when the helmet is being used, must not have sharp edges, roughness or projections such that they could cause harm to the user.

Any element of the helmet that can be adjusted, or removed by the user for the purpose of replacement, must be designed or manufactured in a way that facilitates adjustment, removal or attachment without resorting to the use of tools.

Any adjustment system incorporated into the helmet must be designed and manufactured in such a way that it will not become incorrectly adjusted without the user's knowledge, under foreseeable conditions of use. Industrial anti-blow caps

serve to protect the wearer's head if the head hits hard and immobile objects causing lacerations and other superficial wounds up to self-stunning. Impact caps do not offer any protection against the effects of falling or thrown objects, or moving or suspended loads.

General Regulations

European Reference Standards

EN166 Individual eye protection. Requirements.

EN169 Filters for welding and related techniques.

EN170 Ultraviolet filter.

EN171 Infrared filters.

EN172 Sun protection filters for work use.

EN175 Equipment for the protection of eyes and face during welding and related techniques.

EN207 Filters and protection glasses against laser radiation.

EN208 Protective glasses for laser and laser system adjustment work.

All eye protectors and filters belong to category II of the PPE classification, except for the following, which are category III :

Filters or protectors for hot environments (equal to or greater than 100º) Against ionizing radiation.

Against electrical risk.

Against laser radiation.

Marking

The marking serves to identify the risk against which the eye protector has been certified. This is a code made up of a letter and numbers that indicate the protection specifications.

The first number indicates the type of protection against optical radiation:

2. Ultraviolet

3. Ultraviolet without color alteration

4. Infrared

5. Sunlight

6. Sunlight with specific protection against infrared

The second number indicates the level of protection according to risk expressed in the first.

A single number indicates the degree of protection against various types of welding (from 1.2 to 16).

The letter in parentheses indicates the manufacturer. The next number indicates the optical class (1 to 3, where 1 indicates the best optical quality).

The last letter indicates the level of mechanical resistance.

| Letters | Protector type |

| S = Increased mechanical resistance | Any |

| F = Low energy impact | Any |

| B = Medium energy impact | Full frame glasses or face shield |

| A = High energy impact | Face shield |

Types of eye protectors

Universal frame glasses, Full-frame glasses, Cup-type glasses, Face shields, Welding shields: hand-held, head-mounted, attachable to a protective helmet,...

General Regulations

European Reference Standards

EN149 Filtering half masks for protection against particles.

EN405 Filtering half masks with valves for protection against gases or against gases and particles.

EN140 Half masks and quarter masks.

EN136 Full masks.

EN14387 Gas filters and combined filters.

All equipment belongs to category III (risk of death or serious injury) of the PPE classification. To determine the selection of the mask and/or filter , it is necessary to know: The contaminant, its concentration and its toxicity, The TLV value, The nominal protection factor of the protector, The required protection factor.

TLV or Occupational Exposure Level

is the maximum concentration of a substance contained in the air, calculated as the average over a period of 40 hours per week during which, according to current knowledge, a worker can be exposed day after day without a probable risk to your health.

Nominal Protection Factor

The relationship between the concentration of a contaminant in the environment and its possible concentration inside the mask. It is calculated from the value of maximum allowed internal leakage (%), which is obtained for any equipment from a standardized EN test.

Required Protection Factor : the relationship between the average concentration of the contaminant in the workplace and the TLV.

By dividing the average concentration of the contaminant in the workplace by the TLV of said contaminant, the required protection factor is obtained. Suitable equipment must provide a nominal protection factor greater than the required protection factor. Example:

| Pollutant | Cellulose (solid particle) |

| Concentration | 40 mg/m3 |

| TLV | 5mg/m3 |

| Required protection factor | 40/5 = 8 |

| Recommendation | FFP2 (nominal protection factor 12) |

Replacing filters: it is not possible to determine a filter's effectiveness time, since various factors influence its duration; relative humidity, temperature, respiratory rate, lung capacity, concentration and nature of the contaminant. It is recommended to replace the filter when you notice an increase in respiratory resistance or the smell of the contaminant.

| EN149 masks | EN405 masks | Half masks EN140 | EN136 Masks | |

| P1 particles | 4.5 | 4.5 | 4.5 | 5 |

| P2 particles | fifteen | 12 | 12 | 16 |

| P3 particles | fifty | fifty | fifty | 1000 |

| Gases and vapors | - | twenty | twenty | 2000 |

| Filters for particles, gases, and combined filters | |

| P (white) | Particles class 1 (P1), class 2 (P2), and class 3 (P3) |

| A (brown) | Organic gases and vapors |

| B (gray) | Inorganic gases and vapors (not CO) |

| E (yellow) | Acid gases and vapors |

| K (green) | Ammonia |

Note: These tables are indicative. It must be the preventionist who recommends to the end user which protection is the most appropriate based on measurements in the workplace.

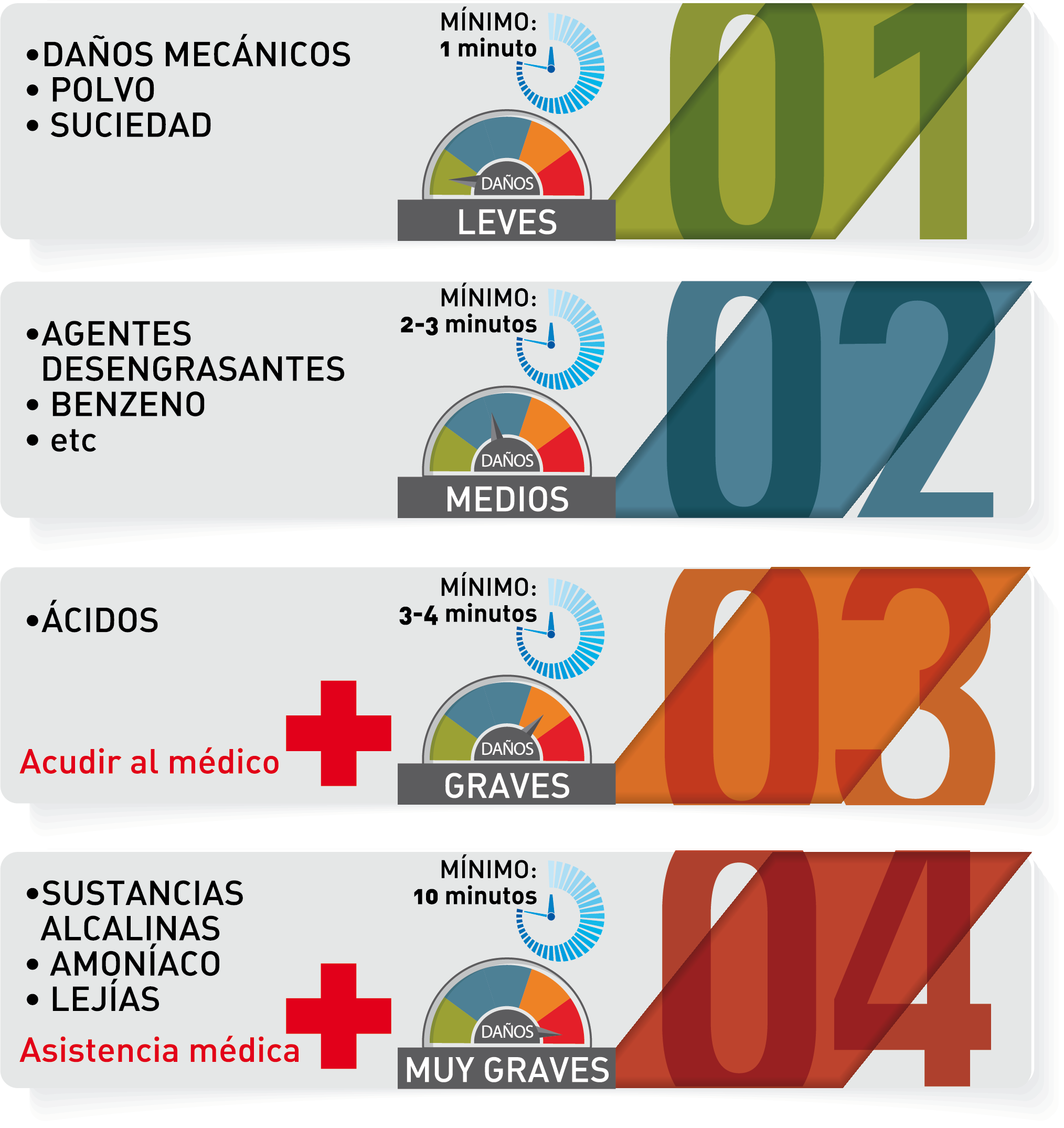

USE OF EYEWASH BOTTLES

"Remember that every second is vital"

| REGULATIONS | |

| EN15154-1 | European Shower Regulations |

| EN15154-2 | European Eyewash Regulations |

| EN15154-4 | European Eyewash Regulations (not connected to the water network) |

| EN ISO 13485 | Health product quality management systems |